Products

Solid and hollow rubber extruded profiles and tubes manufactured in NR, SBR, EPDM, NBR and Neoprene, supplied in black and coloured compounds for sealing, cushioning and industrial applications.

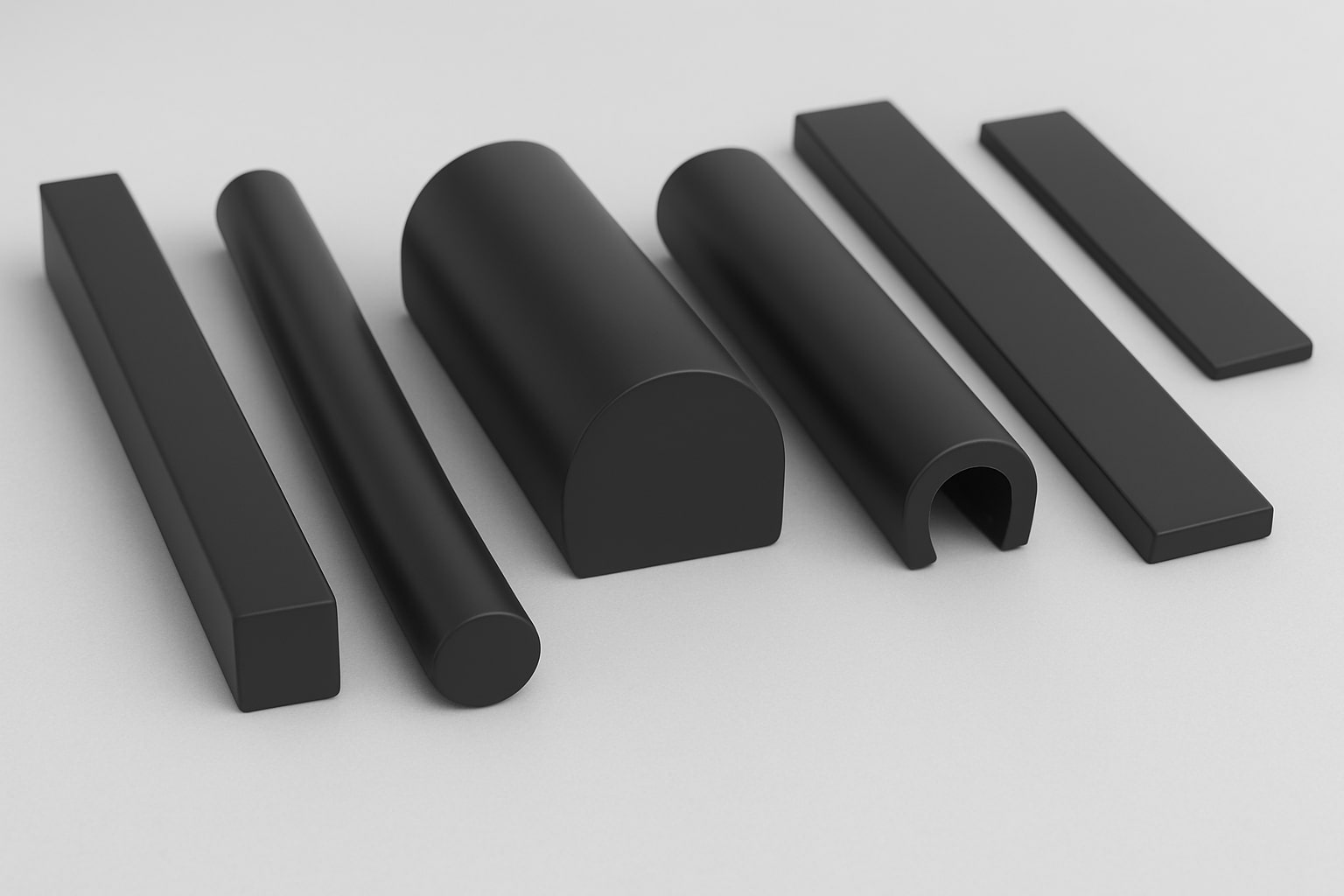

Solid Rubber Profiles

Profiles for general sealing, support and protection in a wide range of assemblies.

Standard Solid Sections

Typical materials: NR, SBR, EPDM, NBR, Neoprene

Square / Rectangular Strips

Cut to length or supply in coils for gaskets, packing and spacers.

Round Cords

For general sealing, edge protection and vibration damping.

D-Section Profiles

Used on doors, hatches and contact surfaces to cushion and seal.

P-Section Profiles

Suitable for frames and edges where a defined contact area is needed.

U-Channels / Edge Trims

For covering sharp edges and providing a neat protected finish.

Custom Solid Shapes

Designed to suit your specific geometry and interface conditions.

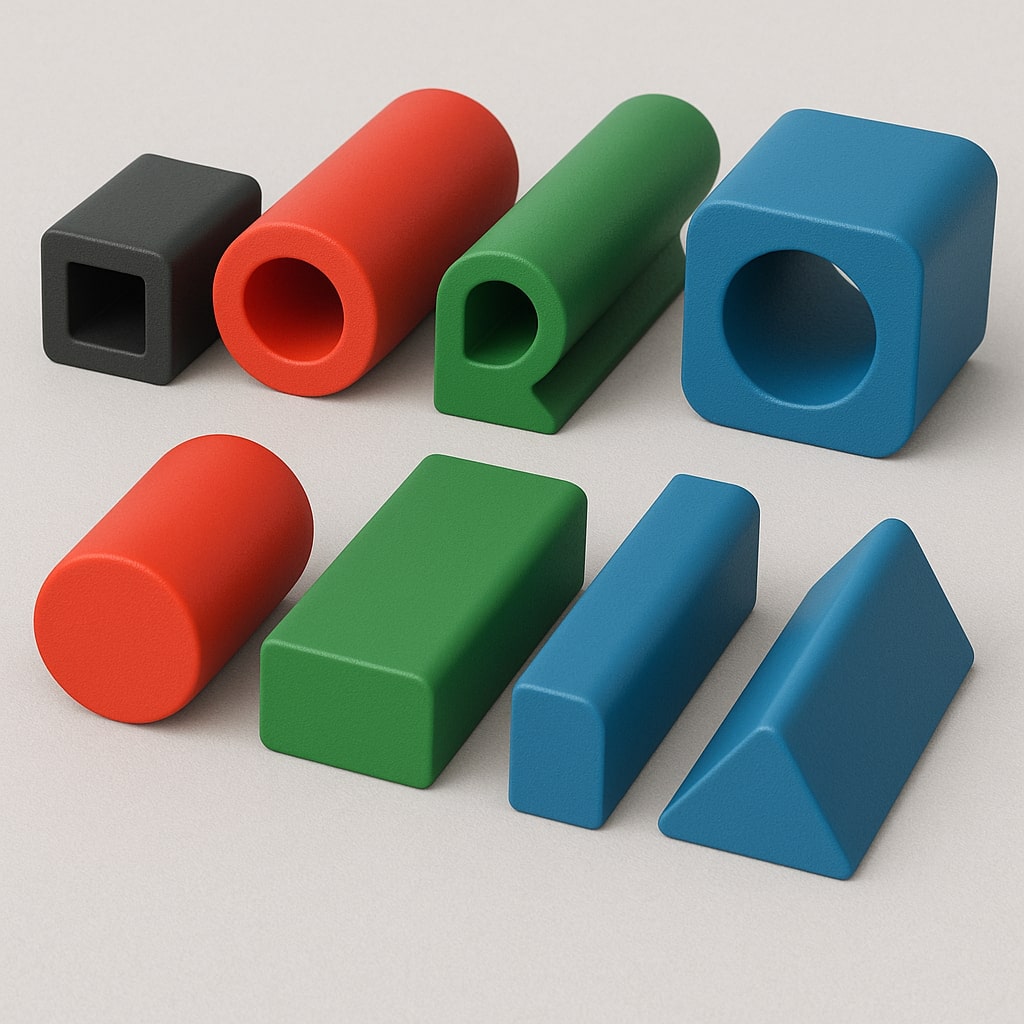

Hollow Rubber Profiles & Tubes

Hollow extruded profiles and tubes designed for flexibility, controlled compression and weight reduction in sealing and protection applications.

Hollow Sections

Developed around your sealing line and load expectations.

Hollow D-Sections

Improved compressibility compared to solid sections for lighter closures.

Hollow P-Sections

Used where a softer sealing response is required on door frames and panels.

Multi-Cavity Profiles

Complex hollows for tuned stiffness and sealing performance.

Custom Hollow Shapes

Built around your drawings to fit grooves, channels or mating parts.

Round Rubber Tubes

Extruded tubes with controlled wall thickness for protection, routing and cushioning.

Square & Rectangular Tubes

Tubes with flat outer faces for mounting, stacking and structural protection.

Custom Tube Sizes

Manufactured to specific OD, ID and wall thickness requirements.

Application-Specific Profiles

For glazing, enclosures and other specialised uses.

Customisation Options

Most profiles and tubes can be adjusted to match your design and assembly needs.

- Material selection: NR, SBR, EPDM, NBR, Neoprene

- Hardness adjustment, typically 40–80 Shore A

- Black and coloured compounds

- Custom OD, ID, width, height and wall thickness

- Die and tooling development for new profiles

- Cut-to-length supply (where required)

- Support for development and production quantities

- Application-based recommendations for compound choice

Looking for a specific profile?

Share your drawing, sketch or sample along with basic operating conditions. We’ll help you select a suitable profile geometry and material.